Full-Service Custom Jacket Manufacturing, Built for Your Brand.

From concept sketch to bulk delivery, Ukleid International manages the entire Private Label Apparel Production lifecycle, specializing in high-quality leather, textile, and hybrid outerwear

Secure Your Production Slot

| Ready to go beyond samples? Secure your place in our Apparel Production Scheduling queue today. Our integrated process, from material sourcing to final quality check, is governed by best-in-class Fashion Supply Chain Management. We guarantee capacity and timeline adherence for high-volume orders for all major markets. |

Explore Material Sourcing

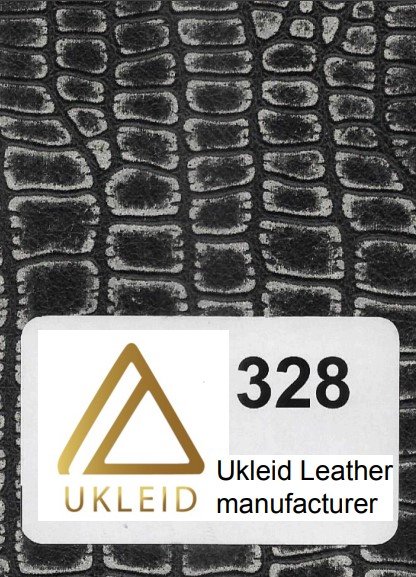

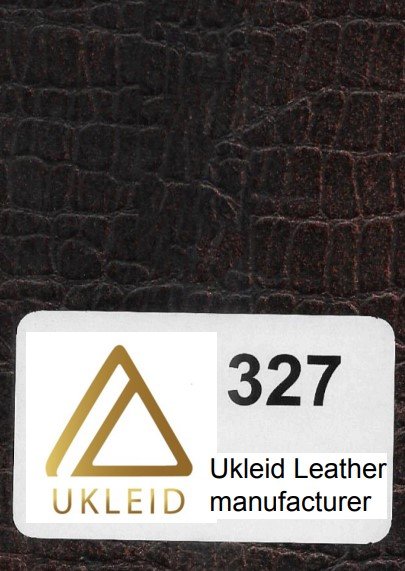

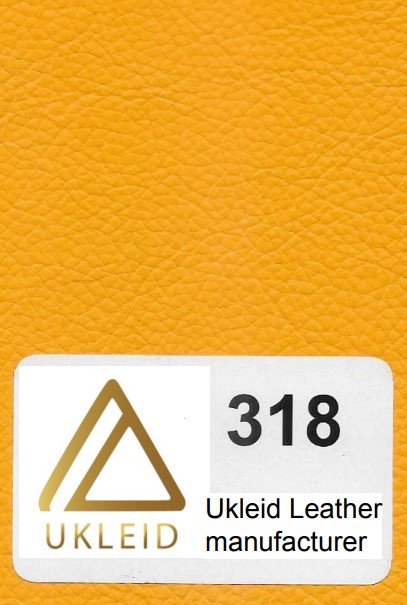

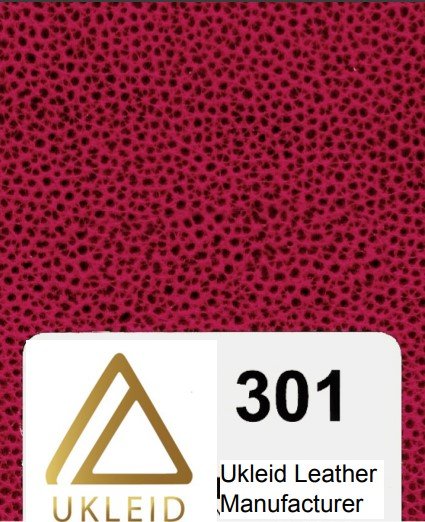

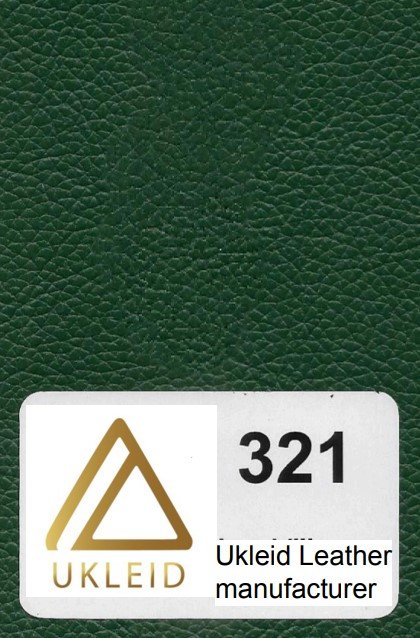

The jacket is only as good as its foundation. Work with our expert sourcing team to find the perfect textiles, hardware, and trims. We specialize in locating certified Sustainable Jacket Materials and ensuring transparent, Ethical Fabric Sourcing to meet your brand’s commitment to corporate responsibility.

Global Logistics & Delivery

Your market is global, and so is our reach. We manage all complexities of customs, duties, and final mile delivery into the USA, Europe, and Australia. Rely on our expertise in International Freight Forwarding and specialized B2B Apparel Shipping to ensure your inventory arrives on time and on budget, minimizing delays.

The Custom Apparel Partner: Beyond Standard Production

From Design File to Finished Goods: Our Transparent 8-Step Process

- Design & Tech Pack Review: Validation of designs and DFM (Design For Manufacturability) review specific to Outerwear Production Process.

- Pattern Making & Grading: Precision digital pattern creation and size scaling to international standards.

- Material Inspection & Cutting: Strict QC on sourced fabrics/leather, followed by efficient lay-up and Cut and Sew Manufacturing process.

- Embellishment & Prep: In-house services for embroidery or printing before assembly (for superior quality).

- Sewing & Assembly: Detail your skilled labor and stitching techniques (e.g., double-needle stitching for durability).

- Washing & Finishing: Mention any specialized washing, distressing, or final pressing to achieve the desired look and feel.

- Quality Control (QC) Check: Final measurement, seam integrity, and material quality inspection. Crucial for Private Label Apparel Production.

- Packaging & Logistics: Custom branding, labeling, packing, and international freight management.

🏆 The Sixth Attempt: Forging the Unforgeable Medusa Leather Helmet

The Challenge: Reimagining a Legend:

When Mr. Mark from Australia approached us, his request was clear but daunting: replicate the legendary Oakley Medusa Leather Helmet. This wasn’t just about crafting a helmet; it was about recreating an icon—a complex fusion of rugged protection, unique organic shape, and premium leather work that few manufacturers dare to attempt. Mark had high standards, and with the original images as our benchmark, the pressure was immense.

The Obstacle: The Path to Perfection

Manufacturing a product with such intricate, multi-layered design and demanding material standards is rarely easy. We quickly learned just how unforgiving this challenge was. Manufacturing a product with such intricate, multi-layered design and demanding material standards is rarely easy. We quickly learned just how unforgiving this challenge was.

Four times we refined the pattern, adjusted the leather treatments, and fine-tuned the stitching. Four times we missed the mark. The shape was close, the fit was off, or the leather didn’t drape quite right. It was a steep learning curve, pushing our team’s expertise to its absolute limit.

We refused to compromise. We understood that Mark wasn’t just buying a helmet; he was investing in a statement piece. Our commitment to uncompromising quality meant going back to the drawing board after every failed sample.

💡 The Breakthrough: Precision and Persistence

On the fifth attempt, we poured over every minute detail, focusing on:

- Material Selection: Sourcing the exact type of supple yet durable leather that could hold the Medusa’s distinctive, flowing form.

- Precision Tooling: Developing specialized molds to ensure the signature ‘dreadlocks’ and visor contours were perfectly symmetrical and structured.

- Expert Craftsmanship: Implementing new, specialized techniques for stitching and internal padding to achieve the fit and feel of the original, while ensuring maximum durability.

The Triumph: Success on the Sixth Try

The samples were shipped. The wait was tense. Then, the feedback came: Success.

Our sixth prototype didn’t just meet Mark’s expectations—it exceeded them. We didn’t just replicate the design; we proved our dedication to mastering the impossible.

“They said it couldn’t be done. We took six tries, and now we are the only independent manufacturer meeting this incredible standard.”

The Result: From Challenge to Consistent Client

Mr. Mark is now a regular and valued customer. His initial request became a defining moment for our company, cementing our reputation as the premier alternative manufacturer for highly specialized, difficult-to-produce leather goods, especially the iconic Medusa.

This case study is a testament to our core values: persistence, craftsmanship, and an unwavering commitment to achieving the absolute best for our clients, no matter how ambitious the request.

Ready for Your Next Production Run?

Don’t let manufacturing complexity hold back your vision. Partner with a dedicated factory for reliable, high-quality Custom Jacket Manufacturing